Lithium battery positive electrode material is part of the material that makes up lithium-ion batteries and directly affects the performance of lithium-ion batteries. The lithium battery system is mainly divided into ternary (nickel, cobalt, manganese) batteries, lithium iron phosphate batteries, solid-state batteries, sodium-ion batteries, etc.

Positive electrode materials are the link with the highest output value in battery materials, accounting for about 40% of the material cost. Positive electrode materials are the decisive factor in the electrochemical performance of lithium batteries, directly determining the energy density and safety of the battery, and thus affecting the overall performance of the battery.

In recent years, the production and sales volume of domestic lithium iron phosphate batteries has continued to rise, and the price of positive electrode materials has also risen significantly, with a large market space.

There are many industrial production processes for positive electrode materials, and the control of temperature, environment, and impurity content is also relatively strict.

Improving the bulk density and volumetric capacity of positive electrode materials is of decisive significance to their practical application. The particle morphology, particle size and distribution of powder materials directly affect the bulk density of the material.

In view of the special requirements of lithium battery positive electrode materials for powder properties, our spray dryers are divided into open and closed types. We have made certain optimizations in atomization performance, system structure and configuration, so that this series of models can obtain better performance indicators. They are widely used in lithium battery positive electrode material products such as lithium iron phosphate (manganese) and are well received by the new energy industry.

How do our products produce positive electrode materials?

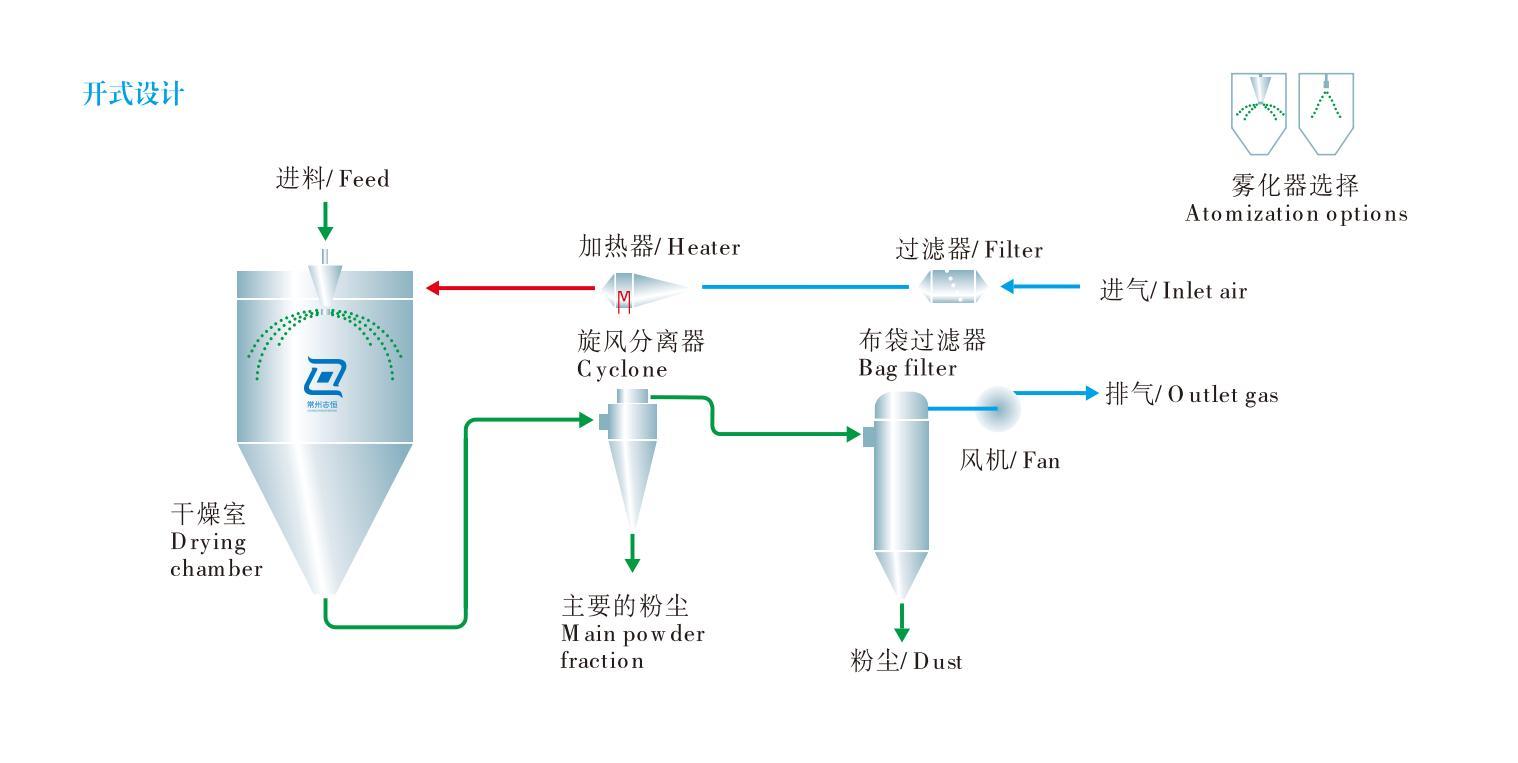

Open spray drying process flow chart

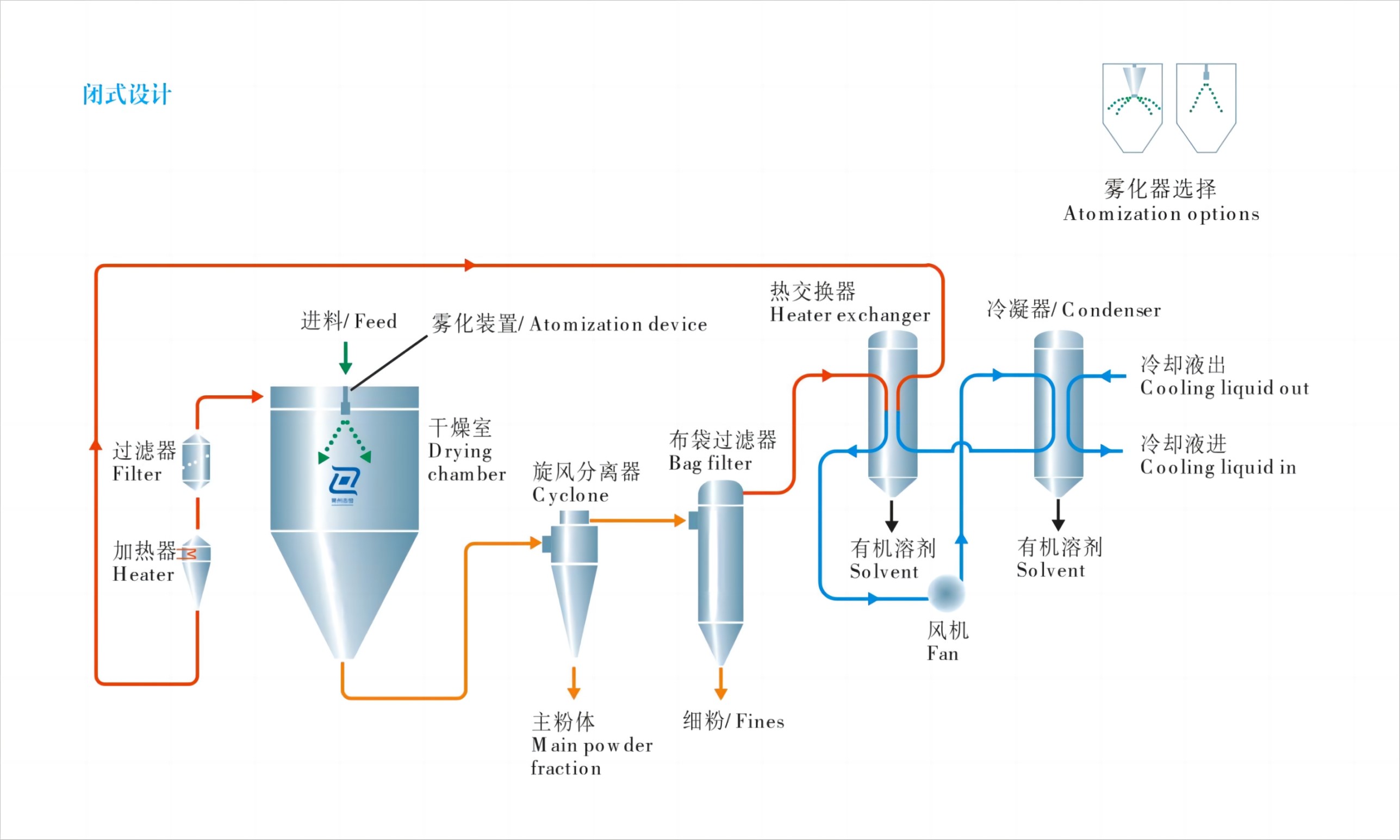

Closed spray drying process flow chart

1. Multiple drying methods can be selected

Our equipment includes open and closed spray drying. Open spray drying is used to treat aqueous phase liquid; closed spray drying is used for organic solvent liquid, with nitrogen as an inert drying medium. In addition, the design of all equipment meets international health and safety standards.

Three atomization methods can be interchanged: centrifugal atomization, air flow atomization, and pressure and air flow dual atomization.

The collection method of powder products can be changed: two-point collection of cyclone separator + bag filter and one-point collection of bag filter.

2. Strong stability of production products

Our equipment can quickly dry the solution of positive electrode material into powder, which not only improves the stability of the product, but also maintains the original performance of lithium iron phosphate (manganese) positive electrode material, such as high safety, long life and low cost, thereby meeting the activity of positive electrode material of lithium-ion battery.

3. Uniform batch production of products

The positive electrode material particles prepared by our spray drying equipment have uniform particle size distribution and controllable morphology. The stoichiometric ratio products you need can be synthesized, and the chemical composition of the material is relatively uniform.

4. Compact structure, remote management

From the structure to the performance design of the equipment, we strictly control the automatic control system independently developed by Zhiheng, which is simple and stable to operate, easy to control, and easy to realize automatic operation.

Zhiheng provides customers with laboratory testing equipment for product property configuration, process development and inspection. Whether your product is still in the early stage of research and development, or is ready to enter the final process essence stage, our testing facilities and experts can provide you with unparalleled equipment and technical solutions.