Powder flavor

Powdered flavors are also called solid flavors, which are generally used in powdered foods and cosmetics such as solid soups, solid beverages, scented powders, and talcum powders.

Among them, sweet flavors and salty flavors are all powdered flavors. Zhiheng's spray drying technology can be used to process aqueous solutions and emulsions. The purpose of drying is to make oily flavors into powdered flavors that are easy to carry and use.

Comparison before and after drying

Powdered flavors are not direct consumer products, but are added to other products as supporting raw materials. Their use has a great impact on the quality and style of the end product.

In recent years, the market size of my country's flavor and fragrance industry has reached more than 40 billion yuan, with a rapid growth rate and great market development prospects. At the same time, people have higher requirements for powdered flavors, hoping to improve health quality and stability.

Although powdered flavors are easy to use, they are easy to absorb moisture and agglomerate, and users should prevent them from spoiling.

In view of this feature, Zhiheng has developed EPSD, ERSD and other series of spray dryers. These spray dryers are specially developed by our company for materials with strong heat sensitivity, poor drying, low softening point, and strong hygroscopicity. They are widely used in the field of food additives and Chinese medicine extracts.

◆ How do our equipments produce powder flavors?

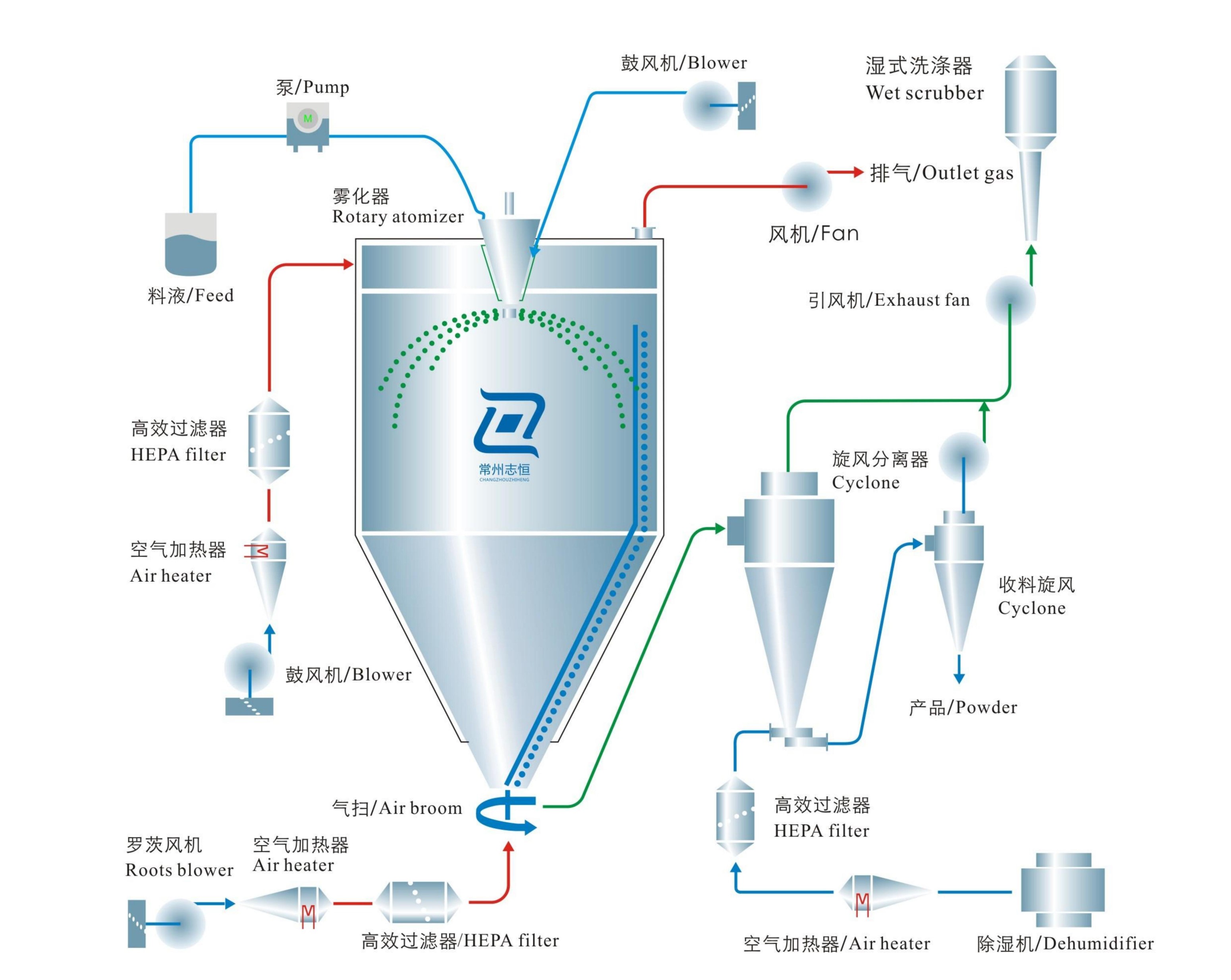

Process flow chart

For many years, Zhiheng has been supplying advanced drying equipment to the food additives and ingredients industry. We are committed to developing world-leading equipment and solutions by continuously improving the design and manufacturing process of the equipment, combined with customers' demand for food quality, to create more added value for customers.

Special design of drying chamber to reduce wall sticking

In view of the characteristics that powder flavors easily absorb moisture in the gas, combine with moisture, and are difficult to further dry, the drying chamber of our equipment adopts a large-diameter design, which can effectively reduce the proportion of fog groups contacting the inner wall.

At the same time, the drying chamber of the equipment is also equipped with an air sweeping device, which cooperates with the large-diameter design to further eliminate or reduce the wall sticking phenomenon.

Cooling system to reduce material coking

In view of the characteristics that powder flavors are highly heat-sensitive and easy to coke and deteriorate, the inner wall and tower top of our drying chamber are designed in the form of air cooling jackets. This design can reduce the temperature of the inner wall and avoid the material from coking and deteriorating due to contact with the high-temperature wall surface, which greatly reduces the waste of materials and increases the success rate of drying.

Powder collection system to avoid material agglomeration

After drying, our powder collection system will use dehumidified air cooling technology, which can cool the product and prevent the material from absorbing moisture, agglomerating and spoiling.

Air filtration meets requirements

Considering the safety of powder flavors, all air intake nodes of our equipment strictly use H13 filtration level, which meets GMP production requirements.

Zhiheng provides customers with laboratory testing equipment for product property configuration, process development and inspection. Whether your product is still in the early stages of research and development or is ready to enter the final process essence stage, our testing facilities and experts can provide you with unparalleled equipment and technical solutions.